How to calculate food product expiry dates

We discuss how important it is to track expiry dates if you are a food manufacturing business.

Accurate expiry dates are an essential part of running a compliant food manufacturing business so it’s important to understand exactly what your obligations are. In this article, we’ll discuss what expiry dates are, how to calculate them for your food products and why they are important.

Need to get your raw material and product inventory under control?

Try Craftybase - the inventory and manufacturing solution for DTC sellers. Track raw materials and product stock levels (in real time!), COGS, shop floor assignment and much more.

It's your new production central.

What’s the difference between a use-by dates and a best before date?

Most regulations involving the production and sale of food require either a best before date or a use by date to be clearly labelled on each of the products you sell to customers. In the food industry itself, this expiry date is commonly also referred to as the “shelf life” of the product.

Depending on your product, you’ll need to define either a “best before” date or a “use by date”.

A use by date is the date by which the product can be safely consumed, provided it has been stored and handled in the correct way. If a use by date on a product is expired, it is generally disposed of. Use by dates are generally legally required on foods that go off quickly, such as meat and fish.

A best before date on the other hand defines a date up to which the quality of the product can be guaranteed. The product can be consumed after this time, however key characteristics such as color or flavor of the product may be degraded. Best before dates are usually used for food that has a longer shelf life, such as canned goods or dry food.

Why is it important for food manufacturers to calculate accurate food expiry dates?

There are a few reasons why it’s a good reason to ensure you are calculating accurate and dependable use by and best before dates for your food manufacturing business:

Food safety - if food goes off before the expiry date, it could make people sick. This is especially important for food that contains meat or fish, as these can cause food poisoning if they’re not fresh.

Customer satisfaction - if food goes off before the expiry date, customers will be unhappy. This could damage your reputation and make people less likely to buy from you in the future.

Legal compliance - in some countries, it’s actually against the law to sell food that has passed its expiry date. So it’s important to make sure you’re calculating food expiry dates accurately to avoid any legal problems.

How do I calculate expiry dates for my food products?

If you’re a food manufacturer, there are a few things you need to do to make sure you’re calculating food expiry dates correctly:

Know the shelf life of your products and materials - this is the amount of time that the food can be stored before it starts to deteriorate. Shelf life varies depending on the food, so you need to make sure you know how long each of your products will last. It’s essential to analyse your production process from your raw materials, manufacturing steps and storage of materials during the process.

Know the storage conditions - this includes things like temperature and humidity. Different foods need different storage conditions to stay fresh for as long as possible. This involves an in-depth knowledge of the microbiological and chemical characteristics of all materials that you use to produce your products. Any potential hazards need to be recorded, analysed and factored into this step.

Use a food expiry date calculator - there are a few different ways to calculate food expiry dates, and using a food expiry date calculator is the best way to make sure you’re doing it correctly.

Label your products correctly - once you’ve calculated the food expiry date, make sure you label your products accordingly. This will help customers know how long they can keep the food before it goes off.

Keep records - it’s a good idea to keep records of the food expiry dates you’ve calculated. That way, if there are any problems with your products, you can quickly check when they were due to expire.

Making a guess on your food expiry dates using data from your competitor products is not a good idea as the quality of their materials and production processes may differ substantially from yours.

Shelf Life Testing

Once a full analysis of your production process is complete and you have an estimate of your desired expiry date you’ll usually then move to the testing phase - this is usually called “Shelf Life Testing”. Most retailers will usually require evidence of this testing before they can accept your products for sale.

This is commonly performed in conjunction with a commercial food laboratory: your product will be tested for safety and quality at various time markers.

For example, if you have calculated that a product should have a shelf life of 6 months then the laboratory will test at Day 0, Day 1, Day 7, Day 14 and so on until the 6 month threshold is passed.

The lab will ask you a number of questions to understand more about the conditions the product was manufactured under and how it is intended to be stored - this information will be used in the test to ensure that it matches with the typical storage and handling conditions that are anticipated. You’ll be expected to provide information about how the product is packaged and the temperature ranges it is expected to be stored under.

Most shelf life testing services will test for the following 6 points:

- pH

- Water Activity

- Salmonella

- E. coli

- Staph. Aureus

- Aerobic Plate Count

- Listeria

- Mold

For each of the markers, you’ll be given a report that summarises the findings at each time stage. If any of the markers are found at an early stage (i.e. Day 1) the test will usually be stopped and a new sample will need to be provided.

Testing your product expiry date

Once you and the laboratory have completed the initial safety tests and an expiry date has been confirmed, it is important to continue to verify this date as you move forward with production.

This is especially important if you change any of your material ingredients or improve your production processes. Other situations that may require a retest of your products include batch or sale pack sizes and new manufacturing equipment (i.e. a new mixer).

Tracking Product Expiry Dates

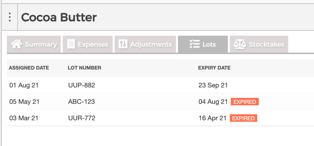

Tracking the expiry dates for all batches of your products is really important - to do this, you’ll need specialised food manufacturing inventory software such as Craftybase that tracks expiry dates, purchases of materials and manufacturing at the batch lot level.

Each individual “lot” of materials you purchase can be assigned a unique code along with an expiry date. These lots can then be associated to individual manufacture records of your handmade products. Expired lots can be easily located and discarded when necessary, and this information can also be applied to each product.

A full traceability report can also be generated for any product or order that you have made, making recalls a fast and efficient process.