How to Scale Your Cosmetic Manufacturing: From Kitchen to Warehouse

You've dreamed of blending your own natural lotions, scrubs, and balms - watching your creations pamper and delight real customers. That spark of excitement is exactly where every great handmade cosmetics brand begins.

Congratulations - you’ve turned homemade creams, balms, and serums into a thriving business! Your dedication, creativity, and relentless late-night batching have paid off in orders, rave reviews, and real momentum.

But with that success comes a new “good” problem: your kitchen now feels less like a cozy workspace and more like a chaotic factory line. Spreadsheets, sticky notes, and memory simply can’t keep pace with growing demand - and every missed step or inventory mix-up erodes your profit and peace of mind.

In this guide, you’ll find a clear, actionable blueprint for systemizing your cosmetic batch production - from cGMP “good habits” and warehouse-ready workflows to automated cost tracking and inventory management for your growing cosmetics business. Let’s turn your chaos into a scalable, stress-free operation so you can grow profitably - and keep doing what you love.

What Does It Mean to Scale Cosmetic Manufacturing?

Scaling your cosmetic manufacturing means evolving from small-batch, kitchen-table production into a professional, repeatable system that can handle growing demand without sacrificing quality, compliance, or profitability. For most handmade cosmetics makers, this transition happens when:

- Your monthly production volume exceeds what you can reliably track in spreadsheets

- You’re considering hiring help or outsourcing production to a co-packer

- Retailers or wholesalers request consistent batch sizes and documentation

- FDA or cGMP compliance becomes a practical necessity, not just a “someday” concern

The cosmetic manufacturing process at scale requires four foundational systems working in harmony: recipe control, real-time inventory, batch traceability, and accurate costing. Let’s explore when you know it’s time to make the leap.

The Tipping Point: 5 Signs You’ve Outgrown Your Spreadsheets

Scaling feels exciting - until you hit that wall where your trusty spreadsheets start fighting back. These common “battle scars” of growth are your signal it’s time for a more robust system:

Spreadsheet Dread You find yourself avoiding that master inventory file because you just know it’s out of date - or worse, riddled with errors. Every time you open it, your heart sinks. That’s exactly where Kasia from Rustic Maka found herself in 2014—her spreadsheets couldn’t keep up with growing SKUs and batch sizes for her natural body care line. After switching to Craftybase, she’s been managing inventory across four sales channels for over 10 years with just a two-person team.

The Costly Stockout You’ve had to pause a huge batch of orders because you unexpectedly ran out of one crucial ingredient - yet it never showed up on your reorder alert. Now you’re rushing last-minute orders (and paying rush fees) to catch up.

Profit Uncertainty Sales look strong on paper, but fluctuating ingredient prices and multiple product variations mean you have no real clarity on what each batch actually costs - so you’re never sure if you’re truly profitable.

The “Which Version?” Problem Your bestselling face oil has three slightly different recipe drafts spread across your laptop, notebook, and email - and you can’t remember which one you used on your last production run. Consistency? Out the window.

Fear of a Recall When a customer reports an adverse reaction, you realize there’s no reliable way to trace which supplier lot or batch of ingredient went into their specific jar. Panic sets in at the thought of potential liability.

If these pain points hit close to home, you’re standing at the tipping point: your handmade cosmetics business needs a purpose-built system to keep pace with your growth - before a small mistake becomes a big one.

The 4 Pillars of Scalable Production

To move from kitchen chaos to a true “cosmetic factory,” professional brands lean on four core pillars. Nail these, and you’ll have a rock-solid foundation for reliable, compliant, and profitable growth.

Pillar 1: How to Manage Cosmetic BOMs & Recipes (Your Golden Record)

Think of your Bill of Materials (BOM) - or simply “Recipe” - as the single source of truth for every batch you make. It’s not just a list of ingredients; it must be:

- Precise: Exact measurements, units, and sequence of steps.

- Version-controlled: Every tweak (e.g., swapping sunflower oil for sweet almond) gets a new version tag.

- Centralized: Stored in one accessible place so every team member (or future hire) follows the same recipe.

When your BOM is bullet-proof, you eliminate guesswork, inconsistencies, and the dreaded “Which version did we use?” drama.

Pillar 2: Real-Time Inventory Management for Cosmetics

With perpetual inventory, every transaction updates your stock instantly:

- Sale of a finished product automatically deducts that item.

- New production automatically consumes the raw materials you used.

Spreadsheets simply can’t keep up - manual errors and delayed updates leave you flying blind. Real-time control ensures you never overcommit or under-order again.

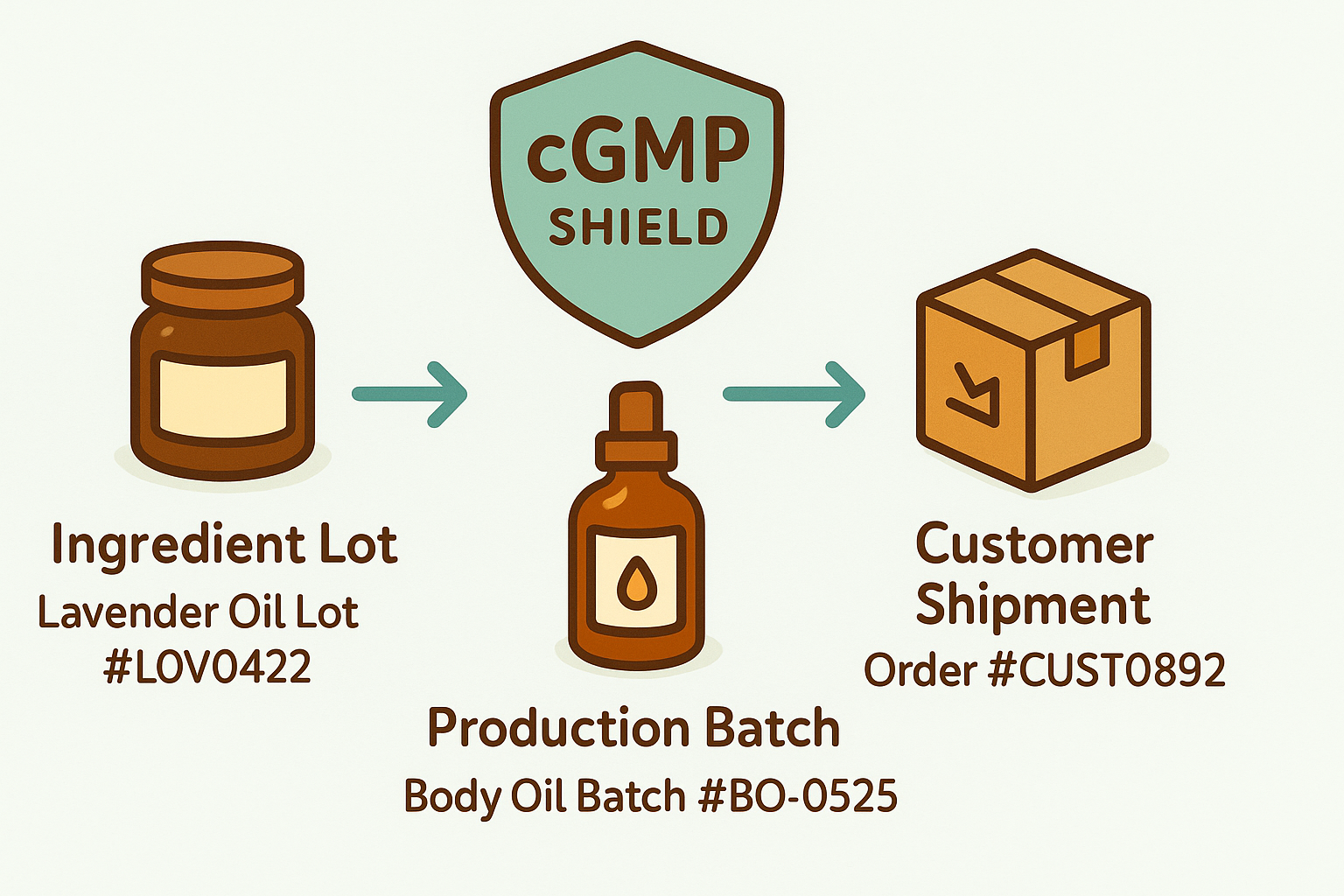

Pillar 3: Meeting cGMP Requirements - Batch Traceability for Cosmetics

Batch and lot tracking isn’t optional - it’s your cGMP shield and recall safety net. You need to trace:

Ingredient lot (e.g., Lavender Oil Lot #LOV0422) → Production batch (e.g., Body Oil Batch #BO-0525) → Customer shipment (e.g., Order #CUST0892)

If a supplier issue or customer reaction arises, you can pinpoint exactly which units to pull - minimizing risk, protecting your brand, and ensuring compliance.

Pillar 4: How to Calculate Accurate COGS for Cosmetic Products

Scaling profitably means knowing the exact COGS per batch - down to the last gram of sea salt or dollop of shea butter. True costing empowers you to:

- Set intelligent retail and wholesale prices

- Plan margins and budgets with confidence

- Identify cost-saving opportunities (e.g., bulk orders, formula tweaks)

When you understand exactly what each batch costs, you can grow strategically rather than guessing your way forward.

Mastering these four pillars transforms your production from ad-hoc hustle to a repeatable, compliant, and cost-effective process - setting the stage for real, sustainable scale.

The System Is the Solution: Moving to a Manufacturing Hub

By now it’s clear: the 4 Pillars simply can’t be managed effectively with a patchwork of disconnected spreadsheets, sticky notes, and standalone apps. You need a central manufacturing hub - one single source of truth for every aspect of your production.

Why spreadsheets fall short at scale:

- Not true databases: They weren’t built to relate recipes, inventory levels, and batch records together - so you end up duplicating data and introducing errors.

- No real-time updates: Manual entry means stock counts, cost changes, and order statuses lag behind actual activity.

- Human-error prone: A missed keystroke or an accidental overwrite can cascade into stockouts, mis-billed customers, or compliance gaps.

- Impossible traceability: Spreadsheets can’t automatically link an ingredient lot to a finished batch and onward to a customer order - you’d have to cross-reference multiple files by hand in an emergency.

What an ideal manufacturing hub delivers:

- Unified Recipes & BOMs that live in one database, with version history and audit trails.

- Perpetual Inventory Management where every sale, production run, and purchase order updates stock in real time.

- Batch & Lot Tracking built-in, so you can trace any finished unit back to its raw-material source - and forward to the customer who received it.

- True Costing Automation that rolls up materials, labor, and overhead into accurate COGS per batch.

- Integrated Manufacturing Orders to plan, schedule, and record each production run - no more juggling separate to-do lists and calendars.

When recipes, inventory, production orders, and costing all live together in one platform, you transform chaos into clarity - minimizing errors, maintaining compliance, and freeing you to focus on innovation and growth. A manufacturing hub is the system that finally lets your business operate like the professional brand it has become.

How Craftybase Becomes Your Manufacturing Hub

Below, you’ll see exactly how Craftybase maps to the four pillars - turning each requirement into a seamless, unified workflow.

For Your Golden Record

Craftybase Feature: Recipe & BOM Management

- What it does: Store every formula as a version‐controlled “Recipe” with precise ingredient weights, units, and process steps.

- Why it matters: Your single source of truth lives here - no more scattered drafts or “Which version?” panic.

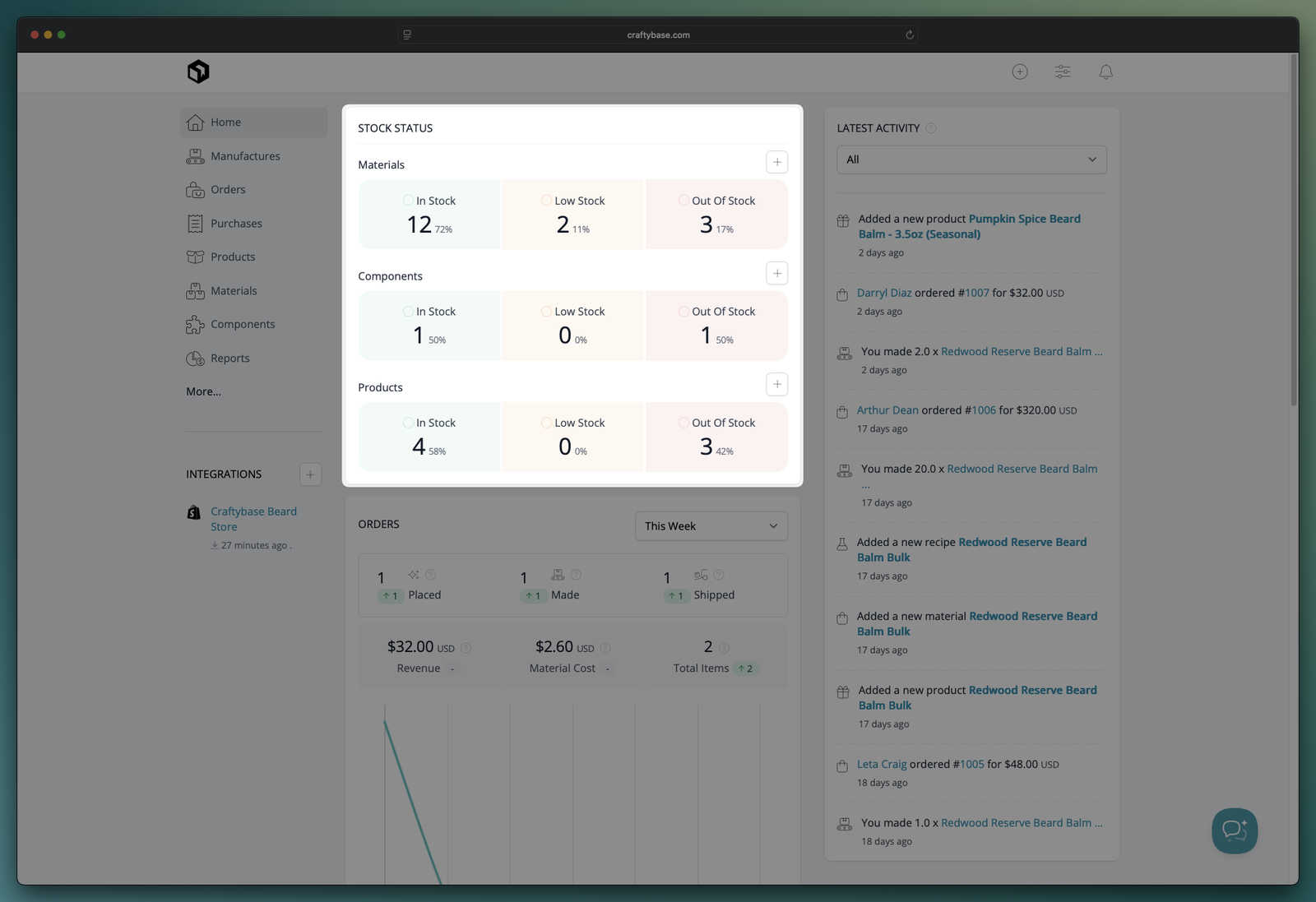

For Real-Time Inventory

Craftybase Feature: Perpetual Inventory Dashboard

- What it does: Automatically adjusts raw‐material and finished‐goods stock levels whenever you record a sale, a purchase order, or a production run.

- Why it matters: You always know exactly what you have on hand - no more manual recounts or surprise stockouts.

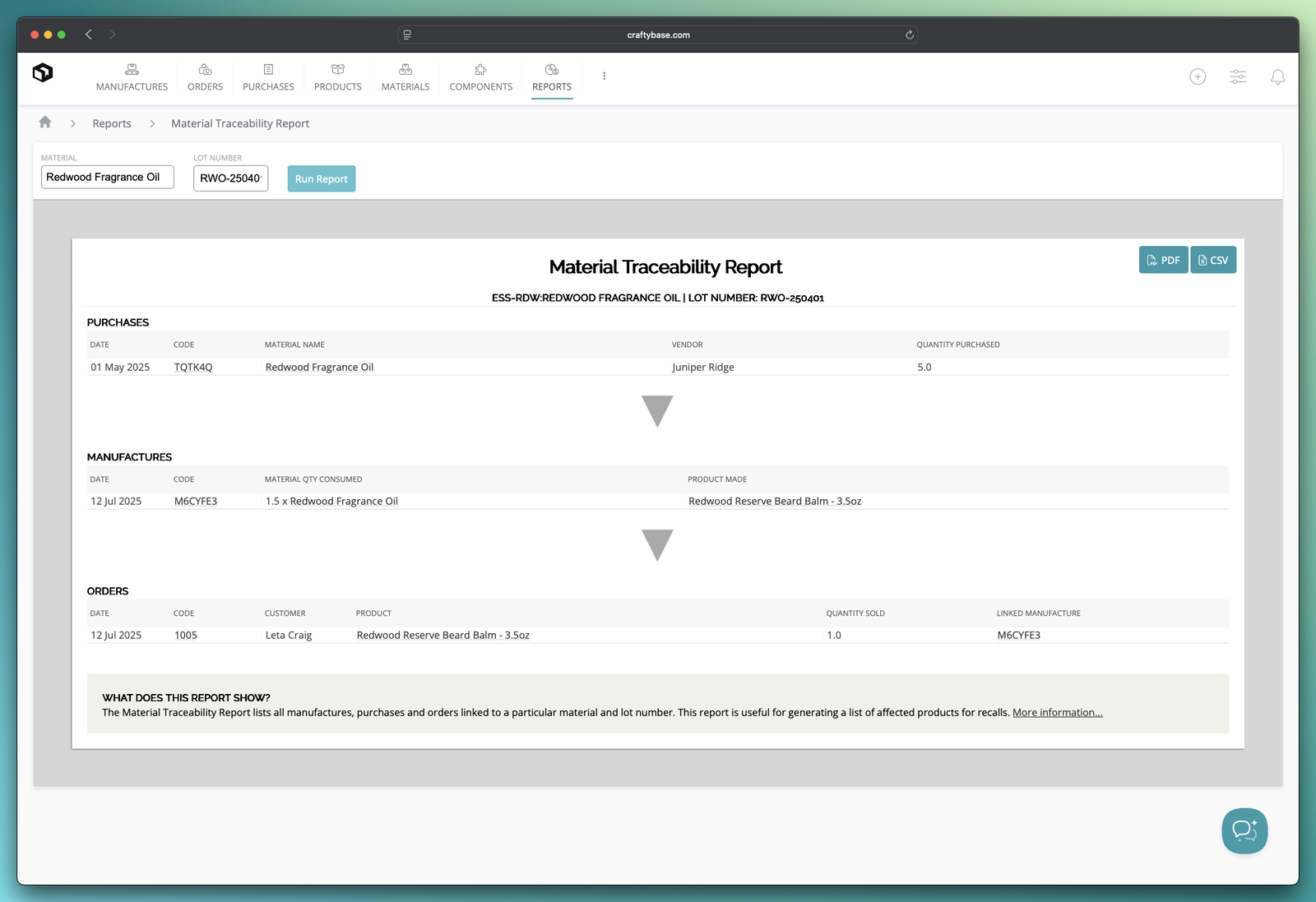

For Absolute Traceability

Craftybase Feature: Batch & Lot Traceability Report

- What it does: Links each finished‐product batch back to the specific ingredient lot numbers used, and forward to the customer orders that received it.

- Why it matters: In the event of a recall or quality issue, you can pinpoint exactly which units are affected - fast, precise, cGMP-friendly.

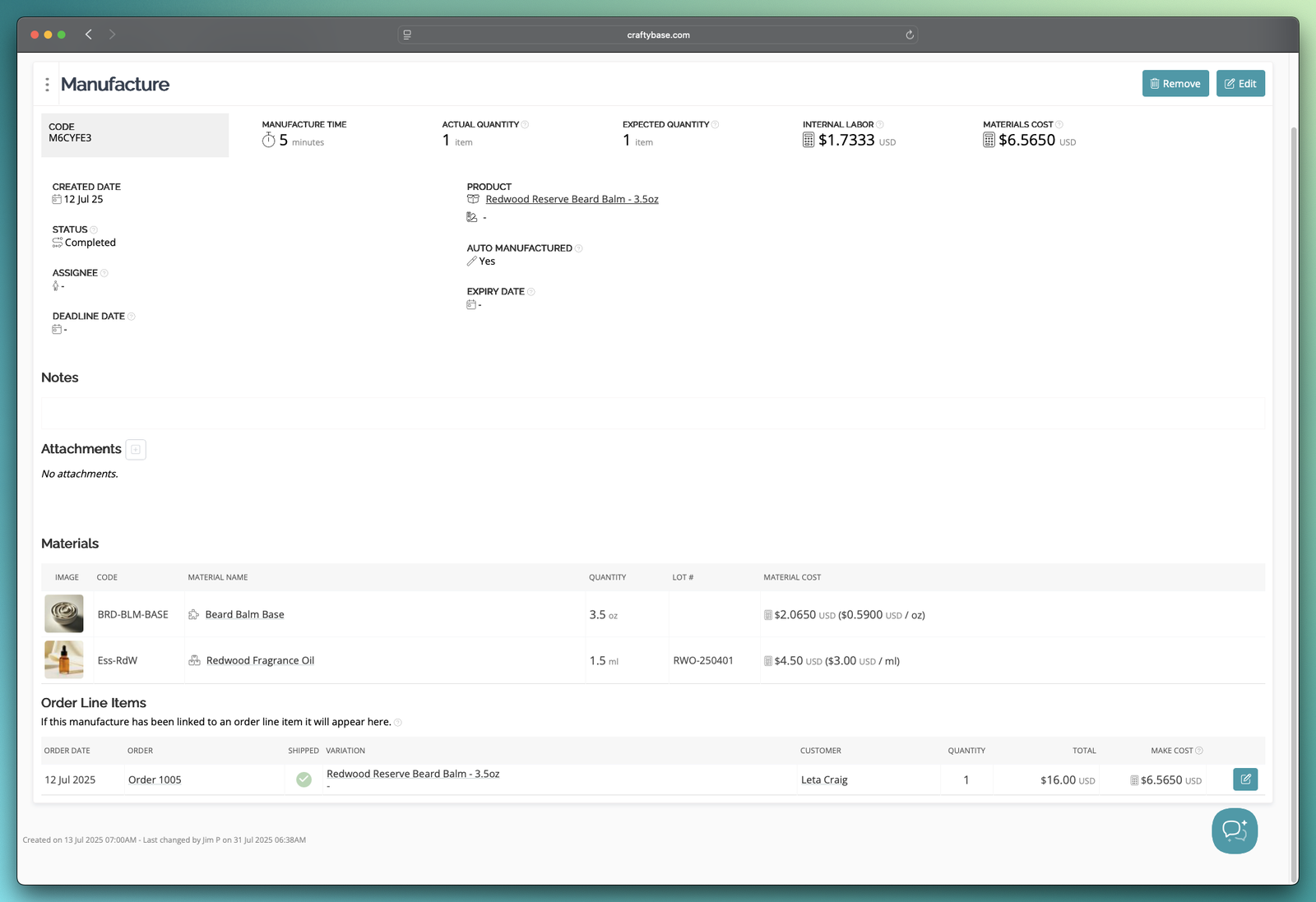

For True Costing

Craftybase Feature: Manufacture & COGS Automation

- What it does: When you confirm a production batch, Craftybase rolls up all material, labor, and overhead allocations to calculate your real COGS automatically.

- Why it matters: You get instant, accurate cost-per-batch figures - so pricing, profitability analysis, and budgeting become effortless.

With everything - from your Golden Record to real-time inventory, traceability, and true costing - living together in Craftybase, you’ll finally have a manufacturing hub that scales with your ambition. Ready to swap chaos for clarity? Craftybase is your next growth partner.

FAQ: Common Fears About Adopting a System

- 💬 Am I too small for this?

✅ If these “Tipping Point” pains—spreadsheet dread, stockouts, profit uncertainty—resonate with you, you're the perfect candidate for a manufacturing hub. The goal isn't to wait until chaos forces your hand; it's to set up a system **before** a single mistake costs you time, money, or peace of mind.

- 💬 Is it hard to set up?

✅ Every new system requires an initial investment of effort—you'll import your recipes, ingredient lists, supplier data, and a bit of historical inventory. But that's a **one-time** process, backed by Craftybase's step-by-step onboarding, video guides, and live support. Once in place, your data works for you automatically, saving you hours every week.

- 💬 Can I afford it?

✅ Think of these systems not as another expense, but as an investment that protects your revenue and sanity. The monthly fee is often less than the cost of a single rushed ingredient order or a spoiled production run. Plus, with real-time costing and low-stock alerts, you'll avoid the hidden losses that spreadsheets can't catch—paying for itself many times over.

Related Resources

Want to dive deeper? Check out these related guides:

- How to Start a Handmade Cosmetics Business in 10 Steps - Perfect if you’re just getting started

- Bill of Materials: The Ultimate Guide - Master your recipe management

- Material Traceability for Small Manufacturers - Deep dive into batch and lot tracking

- FDA Regulations for Cosmetic Makers - Understand compliance requirements

Conclusion

Scaling isn’t just about making more - it’s about making more, smarter. You’ve seen how spreadsheets serve you well at the start, but when you hit the tipping point, a purpose-built system becomes your most powerful ally. By embracing the four pillars - your Golden Record, real-time inventory, absolute traceability, and true costing - you’ll transform chaos into clarity, unlock compliance, and drive profitable growth.

Stop Drowning in Spreadsheets. Start Your Free Trial Today.

Join hundreds of cosmetics makers who've automated the 4 Pillars: bulletproof BOMs, real-time inventory, cGMP-ready traceability, and true costing. Start your free 14-day Craftybase trial—no credit card required, full features unlocked. Most makers save 8+ hours per week.